News

Application of Electron Probe Mioroanalyzer (EPMA) in Aluminum Alloy Microstructural Analysis

Microstructural analysis is one of important standards to control the mechanical properties, lightness, corrosion-resistance, water resistance, and machinability of aluminum alloys. And this task is now becoming easier due to the invention of Electron Probe Microanalyzer (EPMA) from a Japan brand, Shimadzu.

Due to the dramatic advances in science and technology in these recent years, all kinds of products have become smaller and lighter. Aluminum is well known for its lightness and its excellent thermal and electrical conductivity and good ductility. Due to the poor physical strength of pure aluminum, aluminum alloys that have appropriate elements added and are heat-treated to dramatically improve their strength are widely used in various products.

Microstructural analysis is an important criterion to control the mechanical properties, lightness, corrosion-resistance, water resistance, and machinability of aluminum alloys. Shimadzu’s EPMA is a useful tool to achieve these tasks. EPMA is designed with many features that allow it to analysize solid and small materials without destroying the samples.

Here is an analysis of aluminum alloy using EPMA equipment:

Aluminum Alloy Casting

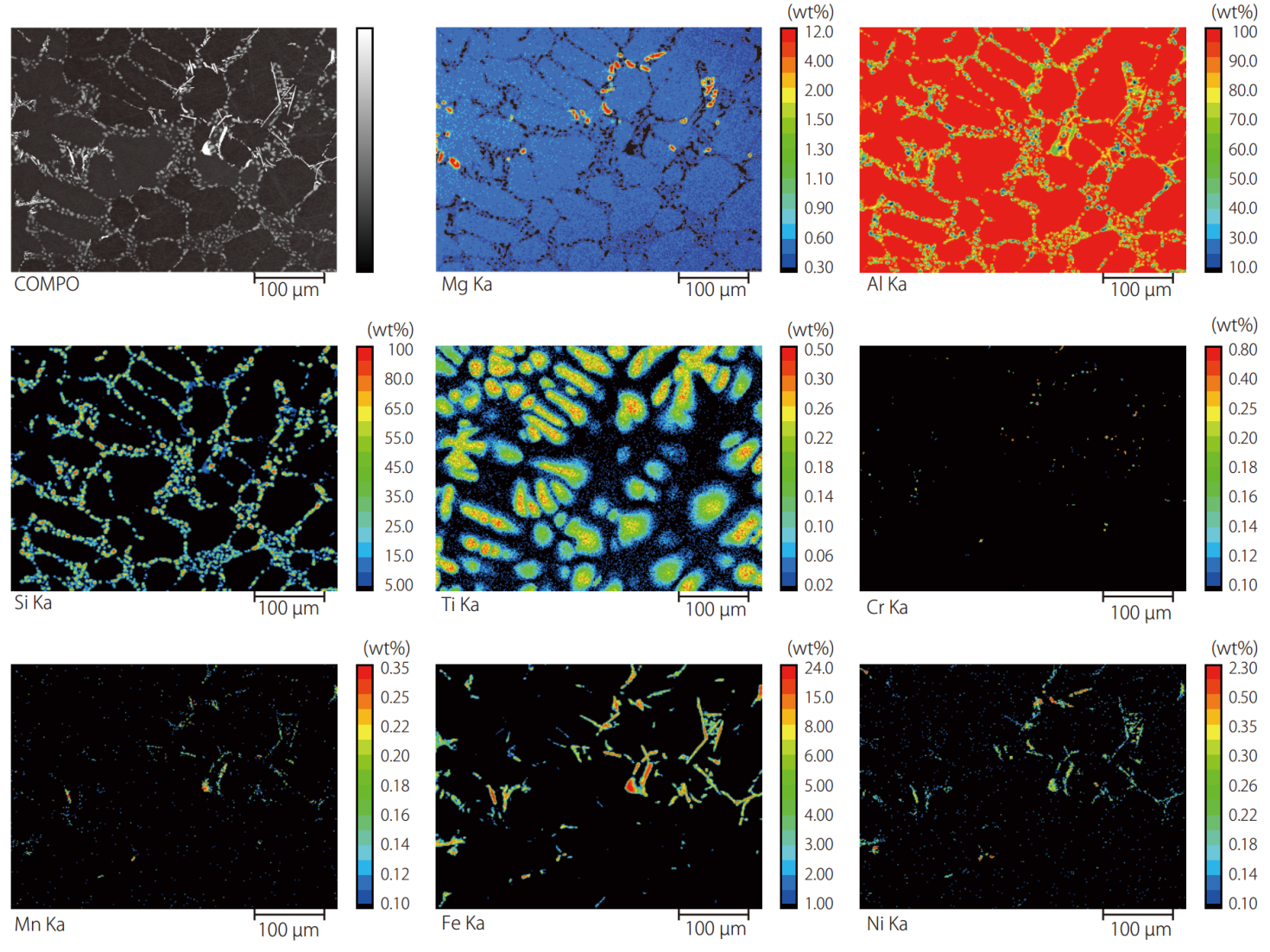

AC4CH (Al-Si-Mg(Fe)) aluminum foundry alloy is widely used for automobile cast components that offer excellent mechanical strength. During the manufacture of AC4CH, spheroidization of eutectic Si particles occurs and banded structures of Mg or Fe-containing intermetallic compounds are formed at areas of eutectic melting.

In Figure 1, the spheroidal eutectic Si is distributed in bands that partially match those at approximately 0.3 % Mg content. It is apparent that coarse intermetallic compounds, such as the 0.2 % max. Fe additive element, exist at areas of eutectic melting.

Fig. 1 AC4CH Mapping Images

Analysis of Intermetallic Compounds

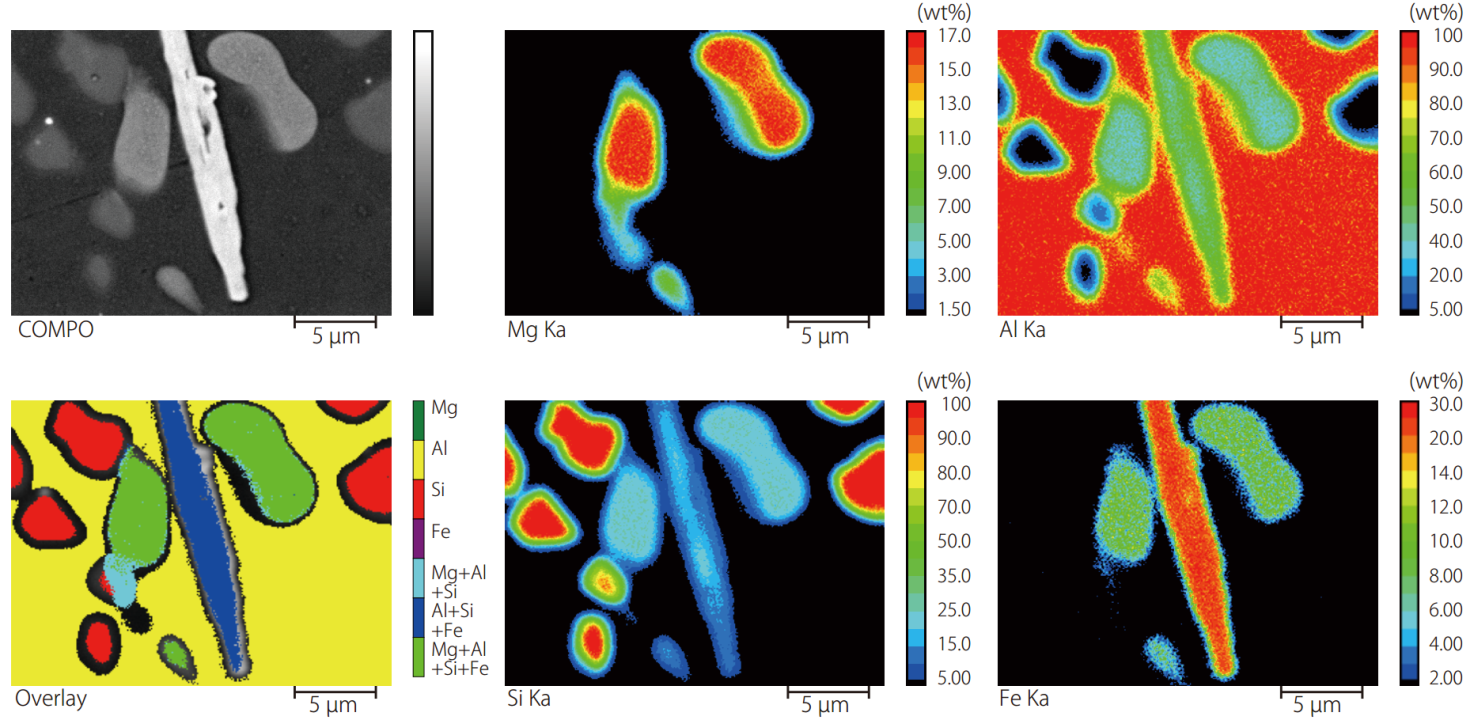

The high-brightness CeB6-EPMA features a new semiconductor type back-scattered electron detector that enables high-sensitivity and high-resolution mapping at lower acceleration voltages than before. Fig. 2 shows a clear-contrast COMPO image at 10 kV acceleration voltage, even of a structure with low average atomic number. Quantitative mapping shows concentration differences for Al, Si, Mg, and Fe.

Binarization each of these four elements at their threshold value and overlaying them produces the overlay image in Figure 2. In this overlay image, the spheroidal eutectic Si is displayed in red and Mg or Fecontaining intermetallic compounds at areas of eutectic melting are displayed in different colors depending on the composition: AlSiMgFe compounds: yellow, AlSiFe compounds: blue, and MgAlSi compounds: light blue.

Fig. 2 X-ray Mapping and Overlay

Analysis of Trace Additive Elements

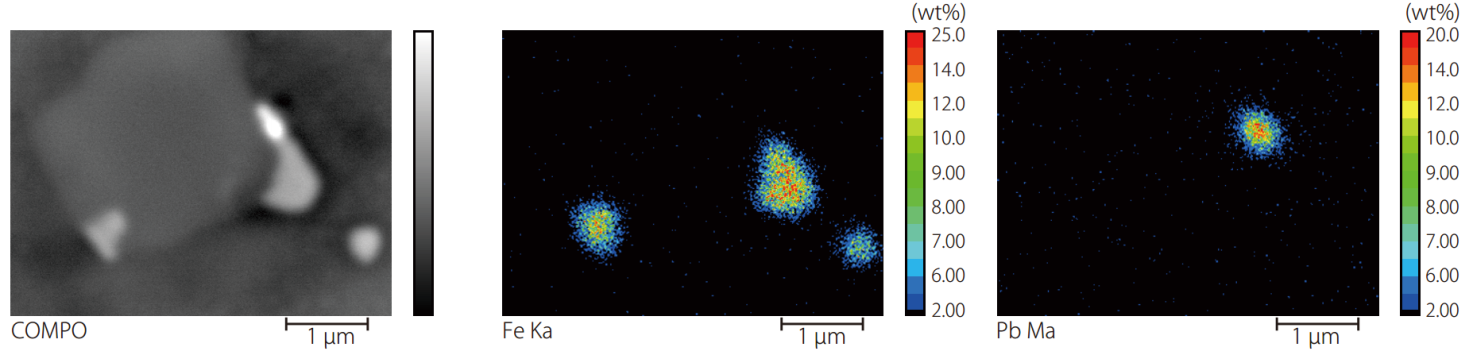

AC4CH (Al-Si-Mg (Fe)) aluminum alloy contains trace additive elements of 0.2 wt% max. Fe and 0.05 wt% max. Pb, which precipitate at high concentration in areas of eutectic melting.

For Al (92.65) Si (7) Mg (0.35), the regions of X-ray generation at 10 kV acceleration voltage are 0.42 µm for FeKαand 0.88 µm for PbMα , which match well with the element mapping image.

Figure 3 Distribution of Trace Elements Added

(Reference from Application NEWS of Shimadzu Corporation)

Source: ETA

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM