News

X-ray CT systems: Powerful tool to employ battery quality

Error inside the industrial product always make the manufacturer feel headache because it can not be observed as well as approached to find the mistake. However, Shimadzu’s X-ray systems which are applied the solution to observe structure inside the object without destroying the sample are useful tools to solve the problem for users.

By simplifying the non-destructive tomographic imaging and 3D imaging of the interior of objects, observations of internal shapes, dimensional measurements, and density observations, these systems are powerful tools for defect analysis and quality control.

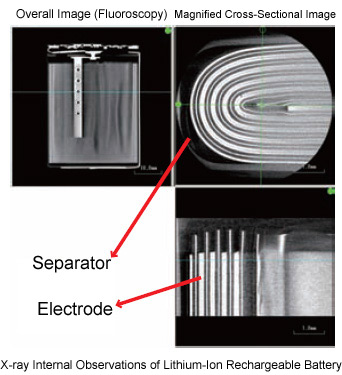

These are images of the electrodes and separators on an arbitrary cross-section.

inspeXio SMX-225CT Microfocus X-ray CT System

Industrial X-ray CT systems offer non-destructive internal observations of objects. A CT system with submicron-level resolution is effective for clearly identifying the internal status of complex electronic components. These systems are employed for final quality control in the battery production process.

Shimadzu released its first X-ray generating equipment for industrial use in 1933 and now has over half a century of experience in this field. Shimadzu improves constantly its product and ensures quality as well as safety.

Source: ETA

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM