Control Engineering and Automation

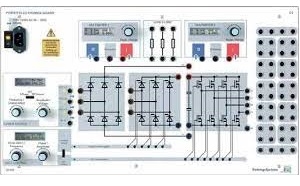

POWER ELECTRONICS TRAINING SYSTEM

Introducion:

- The Power Electronics Training System can be used for training purposes and practical experiments over the entire power electronics sector.

- The system enables investigations of modern drive solutions consisting of frequency converters and motors in a safe low-voltage range.

Training Program:

Becoming acquainted, understanding and applying power electronics components and their functions in rectifiers and inverters:

- resistance

- diode

- coil

- transistor

- IGBT

- thyristor

- MOSFET

- optocoupler

- power electronics components

- rectifier single, rectifier 3-phase, Siebelko full-wave rectifier, rectifier with thyristors

- PWM at MOSFET half bridge, inverter, controlling of smaller motors

Technical Specification:

- Power Electronics Board

- Short circuit proof, feedbackprotected DC 60 V, AC 40 V,60 W

- 3-Channel-DC-Source:

- + per Output -40 V…+40 V, settable

- + max. current per Output 1,5 A

- Alternating current source with setting range:

- + Phase voltage from…23 Veff

- + Max. current per phase...2 Aeff

- + Frequency settable

- Direct and Alternating Current Motors

- DC Motor: Nominal voltage 24 V DC; nominal rotation speed 3000 U/min

- 3-Phase Asynchronous Motor: Star / delta AC3 40/23 V 50 Hz; nominal rotation speed 1250 U/min at 50 Hz

- 3-Phase Synchronous Motor: Star / delta AC3 40 / 23 V 50Hz; nominal rotation speed 1250 U/min at 50 Hz

- Power Electronics

- For experimenting on fundamentals in power electronics, including storage board for the plug-in components and safety bridging plugs, front panel imprinted with the circuit symbols of the components for plug-in modules and safety bridging plugs

Option:

- PC Measurement Interface (90272)

- A 4-channel measuring instrument with differential intputs.

- It allows safe measuring of voltages and deduced magnitudes up to 600V AC.

- Display and evaluation of the measuring results on a connected PC by means of a software.

Sensor Technology

Introducion:

- Expermimenting Board for performing measurement tasks with various sensors, with front panel overlays for a great variety of different experiments.

- Large working area with wiritable color milimeter grid for precise positioning of material samples.

Training Program:

- Functionality of all kinds of sensors in automation

- Determining the sensors required for desired measurements

- Mounting of sensors and subsequent function check

- Designing electric and logical circuits

- Establishing test criteria for function checks

- Diagnosis and analysis of faults

Technical Specification:

- Sensor Board

- Power supply 24V/4.5A, with fuse

- Meter 0...10V/4...20mA, accuracy 0.1%, input via 4mm safety sockets; USB port for configuration

- Sensor terminal for connecting sensors, with 5-pin terminal block, 5-pin M12 socket, 5 safety sockets

- Switch for teaching the sensors, 0V/24V

- 2 signal LEDs for status display of the sensors

- 2 switching outputs (SP1/SP2) DO 24VDC

- 3 plug-in spaces for sensors

- Sensor assortment Basic

- Set of sensors with digital output, consisting of: 1 optical sensor; 1 inductive sensor; 1 capacitive sensor; 1 retro-reflective sensor

Applications set Sensorics Basic

- 6 front panel overlays

- Sensor assortment Advanced

- Set of sensors with analog output, consisting of: 1 optical sensor; 1 inductive sensor; 1 ultrasonic sensor

Applications set Sensorics Advanced

- 5 front panel overlays

- Set of universal sensor holders for adjustment exercises

- Set of material samples

- Set of sensor cables

- USB Programming Connection Line

- Set of safety connections, 4mm

Option:

- Expansion IO-link

- IO-Link Board

- Experimenting Board in A4 format for additional measurement experiments with various IO-link capable sensors

- Sensor assortment IO-LINK Expert

- Set of sensors with IO-link functionality, consisting of: 1 optical sensor; 1 inductive sensor with reference sample; 1 ultrasonic sensor

- Applications set Sensorics IO-LINK Expert

- Sensors for special requirements

- Sensor assortment Cylindrical sensors

- Sensor assortment PT100

- Expansion kit for vibration sensors

- Extension kit for rotary encoder sensors

- Extension kit for sensors - RFID

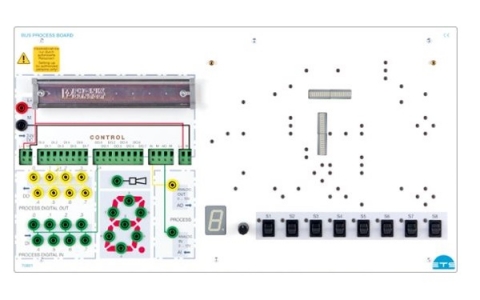

Bus Process Board

Introducion:

- Bus Process Board is used to simulate systems and processes with 9 application masks.

Training Program:

- Configuring complex production facilities with different field bus systems

- Configuring controls with analog and digital I/O terminals

- Setting up decentralized communication-capable automation systems

- Commissioning different field bus systems

- Troubleshooting of master and slave components

Technical Specification:

Bus Process Board

- 8 digital inputs 24 V DC

- 8 digital outputs 24 V DC

- analog module for filling level simulation

- 1 analog input, 1 analog output

- process visualization by LED

- acoustic signal

- fault simulator

- power supply 24 V DC

- 7-segment display

- all in- and outputs on 4 mm safety sockets

Set of application masks

- star/delta circuit; staircase/outdoor lighting; house alarm/burglary; prevention device; traffic light; transfer system with buffer store gate control; industrial processing station; bottle filling station; mixing plant.

Option:

- Available to use with: ET 200, PLC LOGO, PLC S7

Automation Board S7-1200

Introducion:

The ideal tool for getting to know the S7-1200 control or obtaining more in-depth knowledge:

- integrated HMI display

- pushbutton/notched switches for signal input

- potentiometer for analogue value input

- can be expanded using motor control, traffic light etc.

Training Program:

- Setup and configuration of a PLC in the TIA Portal

- Commissioning an automation system

- Programming acc. to international standard IEC1131-3

- Connecting and commissioning field bus systems

Technical Specification:

Function groups:

- 1 CPU 1214C with the integrated features:

- PROFINET interface

- 14 digital inputs, of which 4 for use as rapid counter inputs 100 kHz

- 10 digital outputs

- 2 analog inputs, 1 analog output

- controlled positioning, analog and digital

- PID controller

- 1 Touch Panel KTP700 PN

- 7" colour graphic display with touch function

- additional function keys for free programming

- PROFINET interface

- 1 4-port Profinet switch for Profinet network configuration

- mounted on:

- Automation Board S7-1200

- with short mounting rail and internal 24V DC supply, for universal assembly with S7/1200 components and a 7" touch panel

Option :

- Bus Process Board

- AC Drive Board G120 - 3-phasig

- Servo Drive Board S120

PLC training system S7-1516 Advanced

Introducion:

The ideal tool for getting to know the S7-1500 control or obtaining more in-depth knowledge:

- integrated HMI display

- pushbutton/notched switches for signal input

- potentiometer for analogue value input

- can be expanded using motor control, traffic light etc.

Training Program:

- Setup and configuration of a PLC in the TIA Portal

- Commissioning an automation system

- Programming acc. to international standard IEC1131-3

- Connecting and commissioning field bus systems

Technical Specification:

Function groups:

- CPU S7-1516-3 PN/DP with the following features:

- 2 + 1 Profinet interfaces

- Profibus interface

- 32 digital inputs

- 32 digital outputs

- 8 analog inputs, 4 analog outputs

- 24MB memory card

- Touch Panel TP 700 Comfort

- 7" colour graphical display with touch function

- Profinet interface

- Profibus interface

- 5-port Profinet switch for setting up a Profinet network

mounted on:

- Automation Board Professional

- with short mounting rail and internal 24V DC supply, for universal assembly with S7/1500 components and a 7" touch panel

Option :

- Bus Process Board

- AC Drive Board G120 - 3-phasig

- Servo Drive Board S120

AS-I Field Bus Technology

Introducion:

- AS-I Field Bus Technology is a training system for principles of industrial communication networks Asi, Profibus, Profinet

Training Program:

- Programming PLC and HMI

- Connecting and programming Profinet/Profibus and Asi . networks

- Set up the control network system of conveyor system

Technical Specification:

The system includes:

- PLC training system S7-1516 Advanced

- Transfer system 24V DC

- Field Bus Board ET200SP PROFINET & AS interface

- Profinet bus coupler ET200SP to hold digital and analog extension modules with integrated switch; 2 RJ 45 network connections; incl. server module

- Interface modules: 5 input modules 24V/10A; 2 8xDI modules; 2 8xDQ modules

- AS-i connection module 4DI/4DO: for integrating AS-i in the transfer system

- AS-i command/message station: addressable AS-i slave with; 2 buttons with integrated signal lamps green and red

- PROFIBUS connection module 8DI/8DO: to connect the PROFIBUS into the transfersystem

- Inclusive of the following software:

- SIMATIC STEP 7 professional software (TIA Portal), single license

- WinCC Advanced software, single license

AC Drive Board G120 - 3- phasig

Introducion:

- Already known from the Siemens SCE program, the SINAMICS G120 frequency inverter is now also available as a learning board.

- Whether you are doing exercises for pumping, ventilating, compressing, moving or processing: SINAMICS G120 is the universal drive for the most diverse requirements.

- All connections are led out to the front panel with 4mm safety lab jacks. A motor can be connected either via the laboratory sockets or the parallel available connection socket. The extensive protective functions protect the drive and the connected motor.

Training Program:

- Connecting and starting up drive inverters in compliance with the EMC regulations

- Programming and testing drive and protective functions, interpreting of error messages, trouble shooting

- Central operating and monitoring on the PC, connection with automation systems via PROFINET

Technical Specification:

consisting of:

- Frequency inverter SINAMICS G120 (3 AC-400V)

+ Intelligent Operator Panel (IOP)

+ Profinet interface, 2 ports with integrated switch

+ DRIVE-CLiQ interface

mounted on:

- AC DRIVE BOARD G120 three-phase

+ 3-pole main switch

+ Terminal connections for

4 digital inputs, on 4mm safety sockets and switch

1 relay output, on 4mm safety sockets

1 analog input, 0-10V or 0-20mA, on 4mm safety sockets

1 analog output, 0-10V or 0-20mA, on 4mm safety socket

+ input voltage/frequency: 400V / 50...60Hz

+ output voltage/frequency: 0...400V / 0...650Hz

+ output power: max. 550W

+ Interface for extensions (M12 socket)

- Operating software STARTER

Option:

- Three-phase asynchronous motor 0.25 kW

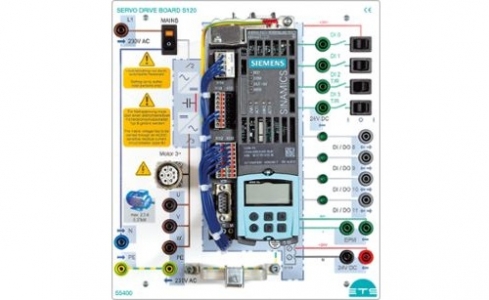

Servo Drive Board S120

Introducion:

- Already known from the Siemens SCE program, the SINAMICS S120 frequency inverter is now also available as a learning board.

- The modular is the modular system for high-performance motion control applications in industrial plant and machinery construction.

- All connections are led out to the front panel with 4mm safety lab jacks. A motor can be connected either via the laboratory sockets or the parallel available connection socket. The extensive protective functions protect the drive and the connected motor.

Training Program:

- Assembly and operation of a servo drive by means of a graphic configuration software

- Adjusting the parameters for current, speed and positioning controls

- Using standard integrated tools for operating and diagnostics

- Optimising the controller settings

- Find out the systematics of reference travel functions

- Create positioning tables with relative and absolute value positioning

Technical Specification:

- Supply voltage: 1 x 230 V AC / 1 x 24 V DC

- Supply frequency: 50 Hz

- Nominal power: 0.37 kW

- Nominal current: 2.3 A

- Output voltage: 0 to 30 V AC

- Output frequency: 0 to 650 Hz

- 1 DRIVE CliQ system connector

- 1 PROFINET interface with 2 ports

- 1 sensor evaluator

- 4 digital inputs with parameter adjustment (floating)

- 4 bi-directional digital inputs / outputs with parameter adjustment (non-floating)

- 1 slot for CompactFlash Card

- 1 safe stop input

- 1 temperature sensor input (KTY or PTC)

- Operating software STARTER

Option :

- Servo Transfer System (80585)

INDUSTRY 4.0

Introducion:

- Comprises all life cycle phases of the product. Products themselves find their way through the manufacturing process. Machines and products communicate with each other and control each other.

Training Program:

- Setup and configuration of a PLC in the TIA Portal

- Commissioning an automation system

- Programming acc. to international standard IEC1131-3

- Connecting and commissioning field bus systems

- Checking function processes and connecting system components

- Adjusting and testing sensors and actuators

- Bus systems, information flow in mechatronic systems

Technical Specification:

consisting of:

- PLC training system S7-1516 Advanced

- Extension for PLC: Trainer Package ET200SP PN IO Link

- RFID System for Profinet

- Transfer system 24V DC

- Station 1: Storage systems - pallet store

- Station 2: Raw Material Storage / Separartion Semi-Parts

- Station 3: Filling Station for Tins

- Station 4: Optical Quality Inspection

- Station 5: Handling station

- Station 6: Assembly / Disassembly (Press)

- Station 7: CPS-I40® Intelligent Storage

Option :

- Robot station with Profinet connection (89992)

- Qbot360- Automated Guided Vehicle (AGV)

Mechatronics System SSC 4.0

Introducion:

- With the mMS Sorting System Compact 4.0, you can teach automation and mechatronics from the basics to complex industrial 4.0 topics and networking in a small space.

Training Program:

The following topics can be teached with the modular Mechatronics Sorting System Compact 4.0:

- Pneumatics and E-Pneumatics

- Mechatronics

- Sensor technology

- Basics for handling industrial systems

- Industry 4.0

- PLC programming

- HMI project planning

- Network technology (wired and wireless)

- IO link

- Coding techniques in an industrial context

- RFID

- IoT

- Maintenance and troubleshooting

Technical Specification:

- 2x Pneumatic Service Unit

- 2x Magazine Unit 1

- Belt Conveyer

- Sorting Unit

- Transfer Point

- Handling Unit with vacuum suction cup

- Assembly Unit

- ASRS-Unit

- IO-Link sensors for measuring the pressure in the pneumatic system

- IO-Link LASER sensor technology for level control

- IO-Link SmartLights (optical display of the system status)

- IO-Link RFID read/write heads (access control and user management)

- RFID transponder for product tracking and control

- RFID transponder for users (access control)

- IO-Link Master (PROFINET)

- Optical sensors to monitor the slides

- Capacitive sensors for monitoring workpiece separation

- 2 SPS SIMATIC S7-1512C

- 2 colour touch panel SIMATIC TP700 COMFORT PN/DP, prepared for intuitive operation

- WLAN antennas (machine-machine communication, human-machine communication)

Option :

- Mechatronics System mMS Station Robotics UR3e (39980)

Servo Robot Station - Table Top Mechatronics

Introducion:

- Amatrol’s Tabletop Mechatronics Servo Robot Learning System proves that you can have all the features of a larger mechatronics system with the space-saving footprint of a tabletop system.

Training Program:

- Programming a Servo Robot

- Programming a Servo Conveyor

- Interfacing a Robot to a PLC

- Function of a Robot-based Inventory System

- Robot-based Inventory System Operation

- Function of a Robot WorkEnvelope

- Programming Conditional Commands

Technical Specification:

The system includes:

- Tabletop Mechatronics Learning System (Three Individual Stations Form One Mechatronics Line)

+ Inventory Station - Table Top Mechatronics

+ Inspection Station - Tabletop Mechatronics

+ Distribution Station - Tabletop Mechatronics

- Pegasus II Robotic Learning System

+ Servo Robot:

Construction: articulated, double jointed, revolute

Axes: 5

Payload: 2.2 lb. (1 kg.)

Repeatability: + .007 in. (.18 mm)

Maximum speed: 23.6 inches/second (599.4 mm/sec)

Actuators: 6 DC servo motors with closed loop control

+ Soft Key Teach Pendant

- 40-inch Linear Traverse

Option :

- Multimedia Courseware

- Servo Robot Station

Tabletop Mechatronics

Servo Robotic Assembly Station - Pegasus

Introducion:

- The Servo Robotic Assembly station trains students for pick and place assembly, and teaches interfacing, problem solving, programming, sequencing and operation for servo robotics, gravity feeders, pneumatic screw feeders, and part insertion. This station performs the role of assembling a working industrial directional control valve using a combination of servo robotic and pick and place technologies.

Training Program:

- Electrical Sensors

- Mechatronics Introduction

- Station Sequencing

- Screw Thread Engagement Module Sequencing

- Screw Feed Module Sequencing

- Part Insertion Module Sequencing

- Automatic Screw Feeder Adjustment

- Station Operation

- Electrical Pick and Place

- Pneumatic Pick and Place

- Mechatronics Safety

- Control Systems Concepts

Technical Specification:

This system include:

- (1) Mobile Workstations

- (1) Operator Station,

- (1) Servo Robot

- (1) Spool Insertion Module

- (1) Screw Feed Module

- (1) Spring/ Knob Feed Module

- (1) Screw/ Knob Engagement Module

- (1) Assembly Shuttle Module

- (1) Finished Parts Storage Module

- (1) Parts Presentation Module

- (1) Pneumatic Distribution Module

- (1) Electrical Distribution Module

- (1) Digital I/O Interface Module

- (1) Electro-Pneumatic Valve Manifold

Option :

- Option: virtual Software

Skill Boss Logistics

Introducion:

- Amatrol’s Skill Boss Logistics offers material handling organizations performance-based assessment for evaluating the skill levels and competencies of future supply chain automation technicians. This system is a working automated distribution system that performs real-world operations, such as package tracking, automatic package queuing and priority release, electro-pneumatic sorting, and much more!

Training Program:

Skill Boss Logistics Evaluates 100 Essential Hands-On Skills in Areas Including:

- Equipment Maintenance

- Equipment Adjustment

- Measurement

- Hand Tools

- System Monitoring & Operation

- Equipment Repair

- Pneumatics

- Mechanics

- Electrical Installation

- System Troubleshooting

- Print Reading

- Network Repair

- Programmable Logic Controllers (PLCs)

- Variable Frequency Drives (VFDs)

- Barcode Readers

- Ethernet Network Test and Operation

- Electronic Installation

- System Troubleshooting

- System Troubleshooting

Technical Specification:

- Use Skill Boss Logistics to Gain MSSC’s CT-SCA Certifications

- Amatrol’s Logistics Automated Sortation System Employs Real Industrial Quality Components

- Comprehensive Online Curriculum Teaches Real-World Logistics Skills

- Skill Boss Logistics Evaluates 100 Essential Hands-On Skills

- Take Troubleshooting to Next Level with Amatrol’s Exclusive Computer-Based Fault Insertion Program

Hydraulic and Pneumatic Systems

Introducion:

- Amatrol’s Basic Fluid Power Learning System – Double Sided A-Frame Bench with Two Hydraulic Manifolds is built to provide for both hydraulic and pneumatic systems training

Training Program:

- Hydraulic Power Systems

- Basic Hydraulic Circuits

- Principles of Hydraulic Pressure and Flow

- Hydraulic Speed Control

- Pressure Control Circuits

- Pneumatic Power Systems

- Basic Pneumatic Circuits

- Principles of Pneumatic Pressure and Flow

- Pneumatic Speed Control Circuits

- Flow Control Valves

Technical Specification:

- A-Frame Double Sided Controls Technology Bench

- Hydraulic Power Supply

- Basic Hydraulic Actuator

- Basic Hydraulic Valves

- Basic Hydraulic Instrumentation Panel

- Hydraulic Hose and Fittings Package

- Basic Pneumatics Actuator/Valve Panel

- Basic Pneumatics Instrumentation Panel

- Pneumatic Hose and Fittings Package

- Bench Manifold Kits

- Additional Requirements:

- Pneumatic power supply or conditioned (dry and filtered) shop air

- Hydraulic Oil

- Hand Tool Package

Option :

- Basic Hydraulics Learning System (85-BH)

- Basic Pneumatics Learning System (85-BP)

- Intermediate Hydraulics (85-IH)

- Intermediate Pneumatics (85-IP)

- Advanced Hydraulics (85-AH)

- Advanced Pneumatics (85-AP)

- Electro-Pneumatics(85-EP)

- Electro-Hydraulics Learning System (85-EH)

- Multimedia Courseware – Basic Pneumatics (MB834)

- Virtual Trainer Courseware - Basic Hydraulics (NB831)

Pneumatic Troubleshooting Learning System

Introducion:

- Amatrol’s Pneumatic Troubleshooting Learning System models a real-world electropneumatic machine, driven by an Allen-Bradley MicroLogix 1200 programmable logic controller, and features over 30 electronically-inserted pneumatic, mechanical and electrical faults using FaultPro.

Training Program:

- In-Circuit Pneumatic Component Testing

- Air Preparation Troubleshooting

- Troubleshooting Pneumatic Cylinders

- Air-Over-Oil System Operation

- Motor and Rotary Actuator Troubleshooting

- Rotary Actuator Operation

- Troubleshooting DCV and Flow Control Valves

- Quick Exhaust Valves

- Troubleshooting Vacuum Systems

- Vacuum Switch Operation

- Troubleshooting Pneumatic Systems

Technical Specification:

Mobile Workstation

- Header System

- Overrunning Load Circuit

- Compression Load Circuit

- Running Load Circuit

- Radial Load Circuit

- Vacuum Load Circuit

- PLC Control Unit

- Allen-Bradley MicroLogix 1200 PLC

- FaultPro USB 4.0 Electronic Troubleshooting Software

- USB Cable and Interface

Utilities:

- Electricity (120 VAC/60 Hz/1 phase)

- Compressed Air Supply

Option :

- Pneumatic Troubleshooting eBook Courseware (EB546)

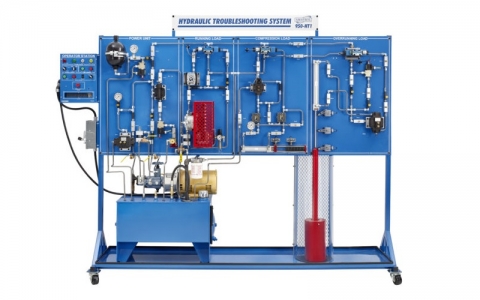

Hydraulic Troubleshooting Training System

Introducion:

- Amatrol’s Hydraulic Troubleshooting Learning System allows users to gain skills such as troubleshooting techniques, system tuning, and pilot-operated DCVs operation. This learning system will also introduce learners to pressure-compensated pumps, pressure-compensated flow control valves, counter-balance valves, and unloader valves.

Training Program:

- Troubleshooting Techniques

- Measurement Methods

- System Tuning

- Startup/Shutdown Procedures

- Troubleshooting Pilot-Operated DCVs

- Troubleshooting Counterbalance Valves

- Troubleshooting Unloader Valves

- Troubleshooting Subplate- Mounted Valves

- Troubleshooting Dial-Type Flow Control Valves

- Troubleshooting JIC Tie Rod Cylinders

- Troubleshooting Hi-Lo Pump Systems

- Troubleshooting Pressure- Compensated Pumps

Technical Specification:

- Mobile Workstation

- Hydraulic Power Unit

- Overrunning Load Hydraulic Circuit Panel

- Compression Load Hydraulic Circuit Panel

- Power Unit Hydraulic Circuit Panel

- Running Load Hydraulic Circuit Panel

- Hydraulic Troubleshooting & Servicing Package

- Control Center

+ Programmable Controller, 20 inputs and 12 outputs

- Manual Learning

- Utilities:

+ Electricity (280 VAC/3 phase)

+ Compressed Air

Option :

- Hydraulic Troubleshooting eBook Courseware (EB544)