News

Barrel Testing System (Part 2)

Systems equipped with modern weapons increasingly require maintenance inspection must take place on a regular basis, to ensure the accuracy and safety during use. For the artillery system, the regular inspection and maintenance of the barrel is always a very important task requiring high precision. To meet this demand, the world now has a number of manufacturers have been developing and testing systems to serve barrel test applications measuring the types of barrel from inside diameter measuring distortion, curvature, applications to measure the parameters of helical grooves, or defects in the barrel.

C. Calibration:

The first calibration is done by the manufacture. All parts of the system contain special features for self-diagnostic. However, the operator should do a periodic calibration once a year or more often if it is required. The system includes special calibration block, which allows checking instrument’s accuracy anytime and fixing calibration table if it is necessary. The calibration takes 10-15 minutes. All calibration processes are automatic.

The calibration block contains a caliber (see pictures), which is used to correlate the readings of the system with factory values in order to check the system's accuracy. The inner surface of the caliber emulates a plenty of pipes with different diameters in all working range. In order to calibrate, the probe should be inserted into the calibration block as it is showed on the picture below. The calibration starts automatically after pushing “Calibration” button.

D. Software

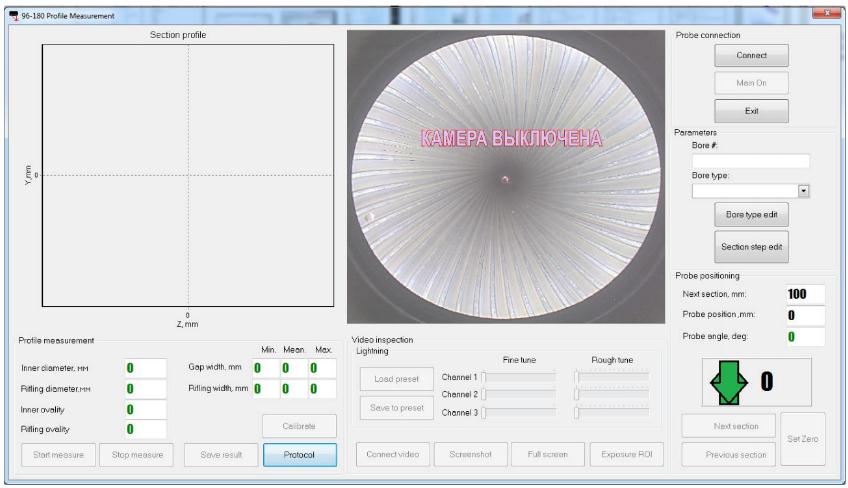

The main form

AREA AND FUNCTION

|

AREA |

FIELDS/BUTTONS |

FUNCTION |

|

SECTION PROFILE |

|

The area for showing the profile of a section |

|

PROFILE MEASUREMENT |

|

The area for showing the parameters of a section |

|

Fields: |

Inner diameter |

Inner diameter The inner diameter in current |

|

|

Rifling diameter |

The rifling diameter in current section |

|

|

Inner ovality |

The inner ovality in current section |

|

|

Rifling ovality |

The rifling ovality in current section |

|

|

Gap width |

The gap width in current section |

|

|

Rifling width |

The rifling width in current section |

|

Buttons: |

Start measure |

To measure in current section |

|

|

Stop measure |

To stop measuring |

|

|

Save result |

Profiles saving into the file |

|

|

Protocol |

To open the protocol form |

|

|

Calibrate |

To open the calibration form |

|

VIDEO INSPECTION |

|

|

|

Lightning |

|

|

|

Buttons: |

Load preset |

To load preset from the internal controller |

|

|

Save to preset |

To load preset from the internal controller |

|

|

Channel 1/2/3 |

Fine and Rough tunes for lighting (separately for each from three channels) |

|

|

Connect video |

To connect a video camera. |

|

|

Screenshot |

To save a current shot to a database |

|

|

Capture |

To start video capturing |

|

|

Full screen |

Switch to full screen mode |

|

|

Exposure ROI |

To change exposure |

|

PROBE CONNECTION |

|

|

|

(Buttons): |

Connect |

To connect with the probe |

|

|

Main on |

To switch all the sensors on |

|

|

Exit |

To exit from the program |

|

PARAMETERS |

|

|

|

(Fields): |

Bore # |

Bore # Number of the barrel |

|

|

Bore type |

Type of the barrel |

|

(Buttons): |

Bore type edit |

To open “Bore type” library |

|

|

Section step edite |

To open “Section step” form |

|

PROBE POSITIONING |

|

|

|

(Fields): |

Next section |

Indication of next section position |

|

|

Probe position |

Indication of current probe position |

|

|

Probe angle |

Indication of current section angle |

|

(Buttons): |

Next section |

To choose the next section in a manual mode |

|

|

Previous section |

To choose the previous section in a manual mode |

|

|

Set Zero |

To set logical O for OZ axis |

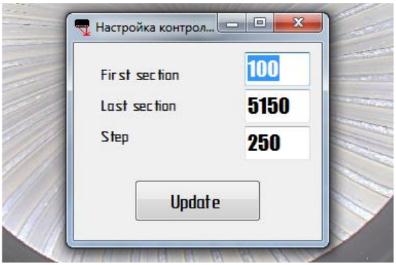

The “Section step” form

|

AREA |

FIELDS/BUTTONS |

FUNCTION |

|

SECTION STEP |

|

The form for determination of macros in automatic mode |

|

Fields: |

First section |

The first section to measure, mm |

|

|

Last section |

The last section to measure, mm |

|

|

Step |

The step between sections, mm |

|

Buttons: |

Update |

To update the macros |

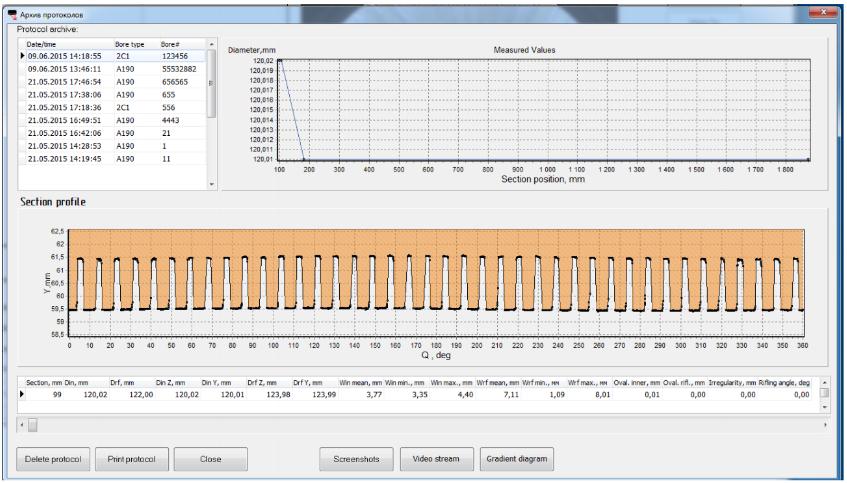

The protocol form

|

AREA |

FIELDS/BUTTONS |

FUNCTION |

|

PROTOCOL ARCHIVE |

|

The list of all saved protocols |

|

MEASURED VALUES |

|

A chart showing an inner diameter for all the length of the barrel |

|

SECTION PROFILE |

|

A chart showing a barrel profile in the selected section (User can switch a circle chart as well) |

|

|

The table below |

Showing all parameters of the barrel in selected section |

|

(Buttons): |

Delete protocol |

To delete the selected protocol |

|

|

Print protocol |

To print the selected protocol out |

|

|

Close |

To close the form |

|

|

Screenshot |

To show/print out a screenshot for the selected section |

|

|

Video stream |

To play a video stream |

|

|

Gradient diagram |

To show/print out a gradient diagram for the selected protocol |

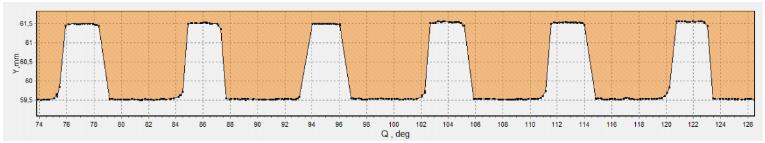

The protocol form (Zoom mode)

Source: RSI

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM