News

HARDNESS TESTING

Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting.

Hardness is not an intrinsic material property dictated by precise definitions in terms of fundamental units of mass, length and time. A hardness property value is the result of a defined measurement procedure.

Common hardness testing types include :

- Rockwell testing is the most commonly used method by virtue of the quick results generated and is typically used on metals and alloys; advantages: No optical system required, not depent on operator’s skill, less affected by the surface roughness.

Rockwell hardness tester DAKOMASTER 300

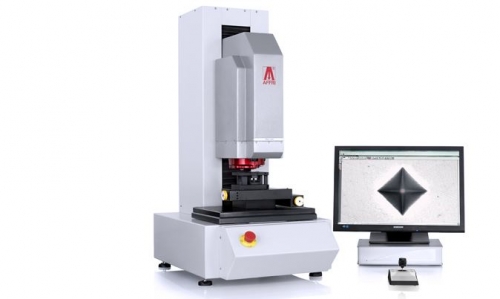

- Vickers testing are more suitable for thin materials, coatings, and mounted metallographic components.

Vicker hardness tester WIKI 200 JS4

- Brinell testing applications generally include large, inaccurate devices such as cast irons, large steel frames and aluminum; not for testing hard materials, thin plates or curved surfaces.

Brinell hardness tester Integral 1

Scale:

- Rockwell testing: HRA, HRB, HRC, HRD...

- Vickers tessting: HV

- Brinell testing: HB

Source: TECOTEC HCM

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM