News

Method For Verifying Short (Zero) Connection When Using Kelvin Klips

Kelvin Klips are four-terminal connector clips designed to provide rapid, precise connections to a device or unit under test (DUT/UUT). Used properly, Kelvin Klips eliminate measurement errors caused by lead resistance and/or improper connections.

Kelvin Klips Require Zero Verification

To ensure proper operation of an instrument with Kelvin Klips, a short (Zero) verification should be part of your standard work practices. This ensure that all four wires of a Kelvin Klip set are intact and firmly operational. Without this verification, you run the risk of significant measurement error.

Procedures for a Proper Short (Zero) Test

Short (Zero) tests should be performed when:

- The test instrument/meter has not been used for a period of 6 hours or more.

- The test set-up has been changed.

- The DUT/UUT has changed significantly.

- Test procedures call for such verification.

- Uncertainty or change has been introduced into the test set-up or environment.

The basic procedures follow:

- Apply power to the instrument and allow adequate warm-up. In a temperature controlled lab, you should allow at least 20 minutes warm-up time for stable readings. If the instrument’s environment is not well controlled, allow 60 minutes for warn-up.

- Connect the leads of the Kelvin Klips to the input jacks.

- Establish instrument settings (Measurement function in lowest range)

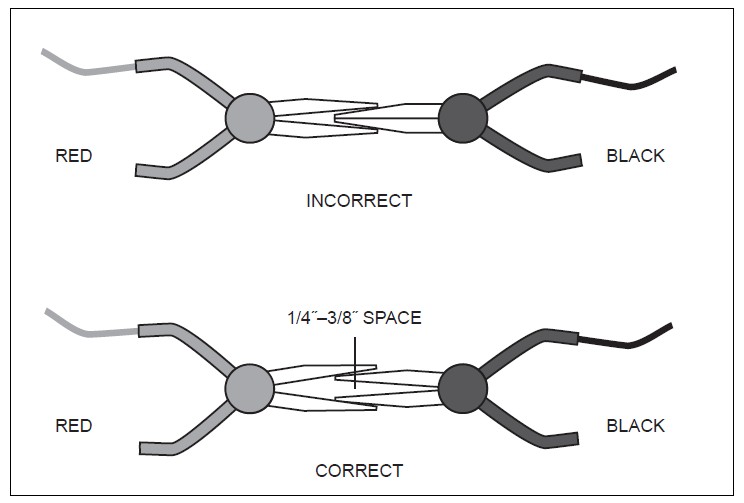

- Short the Kelvin Klips together as figure below (Creating a 1/4 ~ 3/8 inch space between its jaws, Do not clamp Kelvins Klips directly together).

- Verify that the reading on the digital instrument display is within 5 counts of zero.

Source: TMC

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM