News

MILLI-OHMETE SERIS 710A AND 720A TEGAM

Reliability and accuracy are a very important factor for any measuring device. With Milli-ohmmeter 710A and 720A TEGAM, you can be assured of making your measurements without worrying about accuracy and reliability.

About 710A và 720A Milli-ohmmeter TEGAM.

This is a new micro-ohmmeters series with high-accuracy (0.2% of results + 0.02% of measuring range) of TEGAM USA. They are designed to allow the most information to be displayed and clearly visible to the user to capture more information. Measurement time is also be reduced but still ensuring accuracy and reliability.

Designed for single-handed use, the 710A and 720A can be comfortably carried and used for extended periods of time.

Specification:

- Resistance range: 10mΩ - 100Ω

- Accuracy: ±(0,2% reading + 0,02% Range)

- Reading rate: 3 reading per second

- 4-digit Auto-Ranging with Backlight and Function Annuciators

- 4 wire measurement

- Power Supply: 3 pin AA

- Life time: 100 hour (Standby mode); 50 hour (Continuous use)

- Demension : 193 x 84 x 28 mm

- Weigh: 303,2g

Model 710A and 720A are able to perform on-site calibration and calibration of objects with laboratory-grade accurate results. Measurements can be made in many different environmental conditions and still give accurate results.

Application of 710A and 720A Milli-ohmmeter TEGAM: The measurement of small milliohm resistor is essential in many different engraving areas, we can mention as:

Aerospace: Verify mechanical and electrical bonds for safety, conductivity, mechanical integrity, RF shielding and lightning protection. TEGAM is the largest provider of bond meters/milli-ohmmeters to the US Armed Forces..

Alternative Energy: Solar arrays and wind turbines are prone to lightning strikes. The integrity of their grounds must be maintained and restored after an event. A small increase in the resistance translates into a dangerous voltage when thousands of amps are flowing..

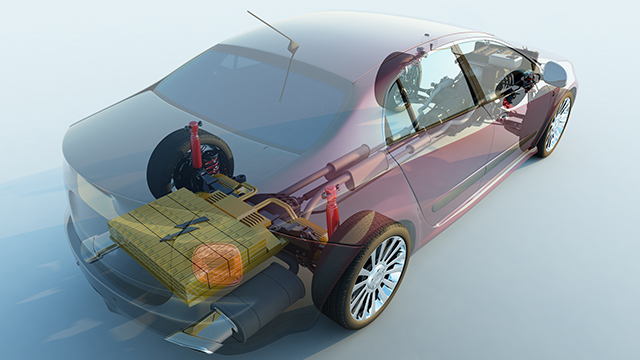

Automotive: Battery Electric Vehicles contain many high current interconnections and over current protection. Verifying the low resistance is essential to preventing fires and poor performance. Conventional ICE engines also rely on many electric systems that are verified with TEGAM instruments.

Electronics: Validate circuit board elements and traces with low resistance measurements that can detect thin or undersized conductors. Check connections and current limiting resistors in situ.

Electrical Systems: The 710A milli-ohmmeter is sensitive enough to detect loose bus bars, damaged shunts, failing fuses and poor cable terminations.

Source: TMC

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM