News

Quality control process of smart phone in Samsung Application of Shimadzu's SMX-225CT FPD HR system

At present, Samsung is one of the world's leading manufacturers of smart phones. Recently, however, there were some incidents led to the explosion of mobile phones, which has impacted greatly on the company's production.

In order to ensure that phone problems do not recur, Samsung has established a strict quality control process for the smart phone.

Samsung's smartphone must pass tests such as long-term performance checks, bumps, bends, water or harsh environments. After all the above processes, Samsung's smartphone is put into an X-ray defect machine to see if there are any faults on the products.

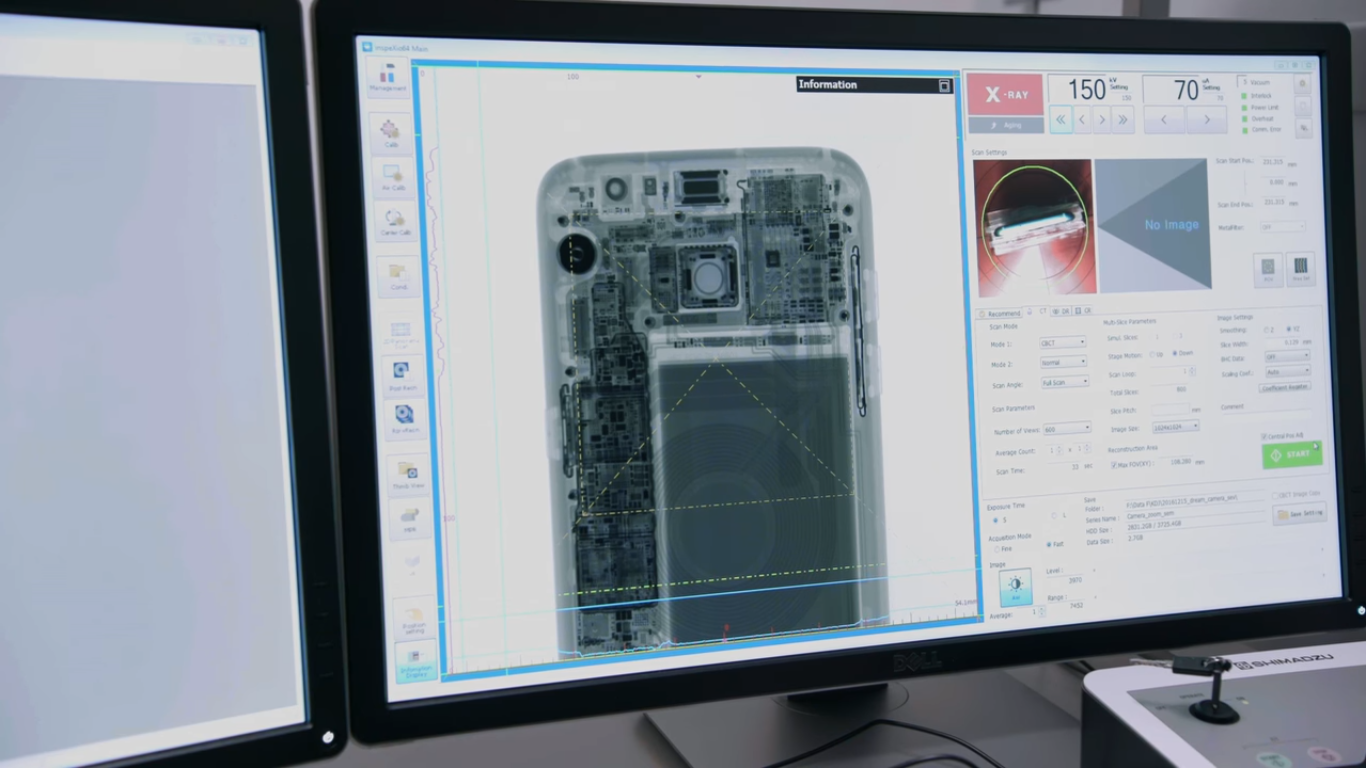

Figure 7a. Check the components inside the smart phone with the SMX-225CT FPD HR system

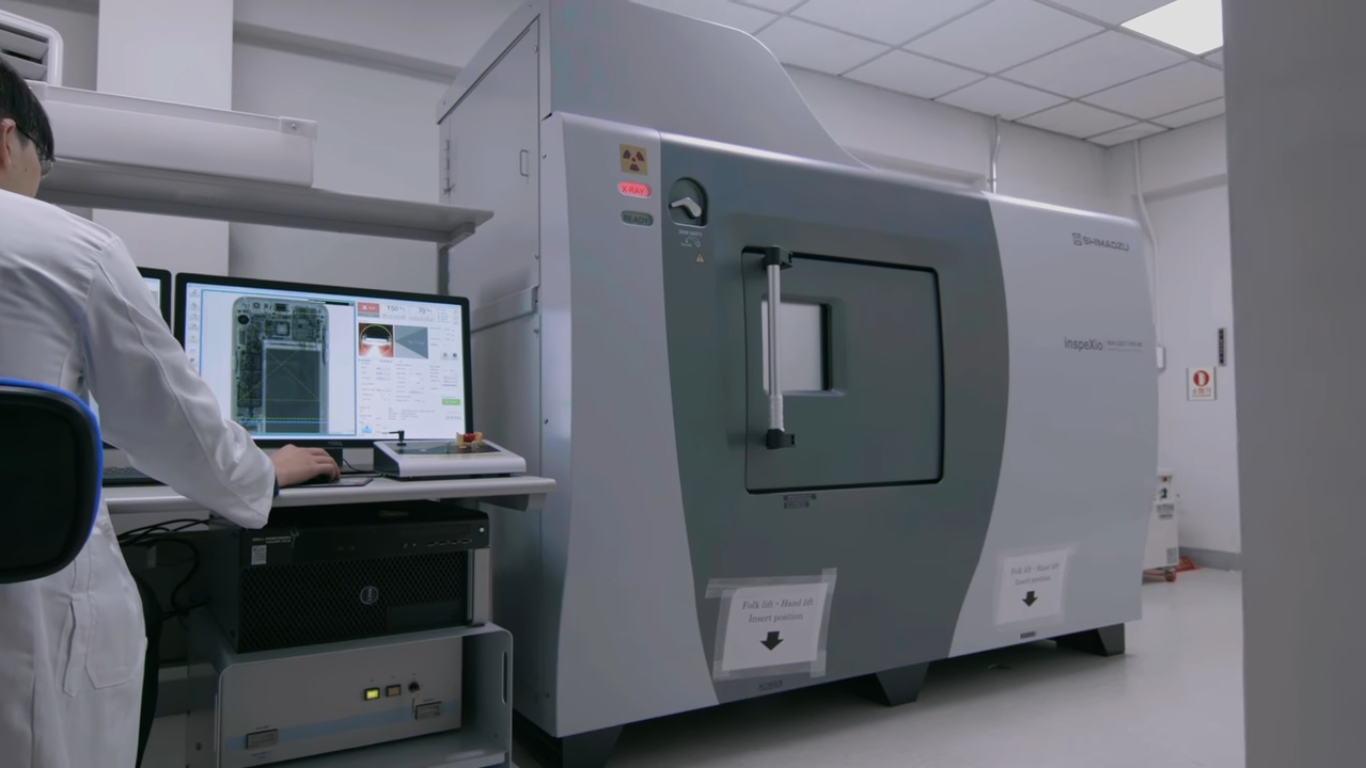

Figure 7b. Check the components inside the smart phone with the SMX-225CT FPD HR system

Details of the quality control process is shown in the video link below:

https://www.youtube.com/watch?v=1JJDtHTFzlY&feature=youtu.be

In the video introducing the quality control of smart phone, Shimadzu's SMX-225CT FPD HR system appears in the X-ray Scanning section. The system is not only inspecting the components of smart phone but also rendering 3D objects of interest through product scanning with X-rays.

With world-leading features in the ability to inspect the components inside the phone, Shimadzu's SMX-225CT FPD HR system has been trusted by Samsung to equip this system for all of plants around the world..

Source: ETA

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM