News

Sample Pretreatment for Optical Emission Spectrometry

Today, for the steel industry in particular as well as metallurgical and other non-ferrous metals, using spectrophotometers to manage and monitor the chemical composition of metallic materials and alloys is a indispensable in production stages.

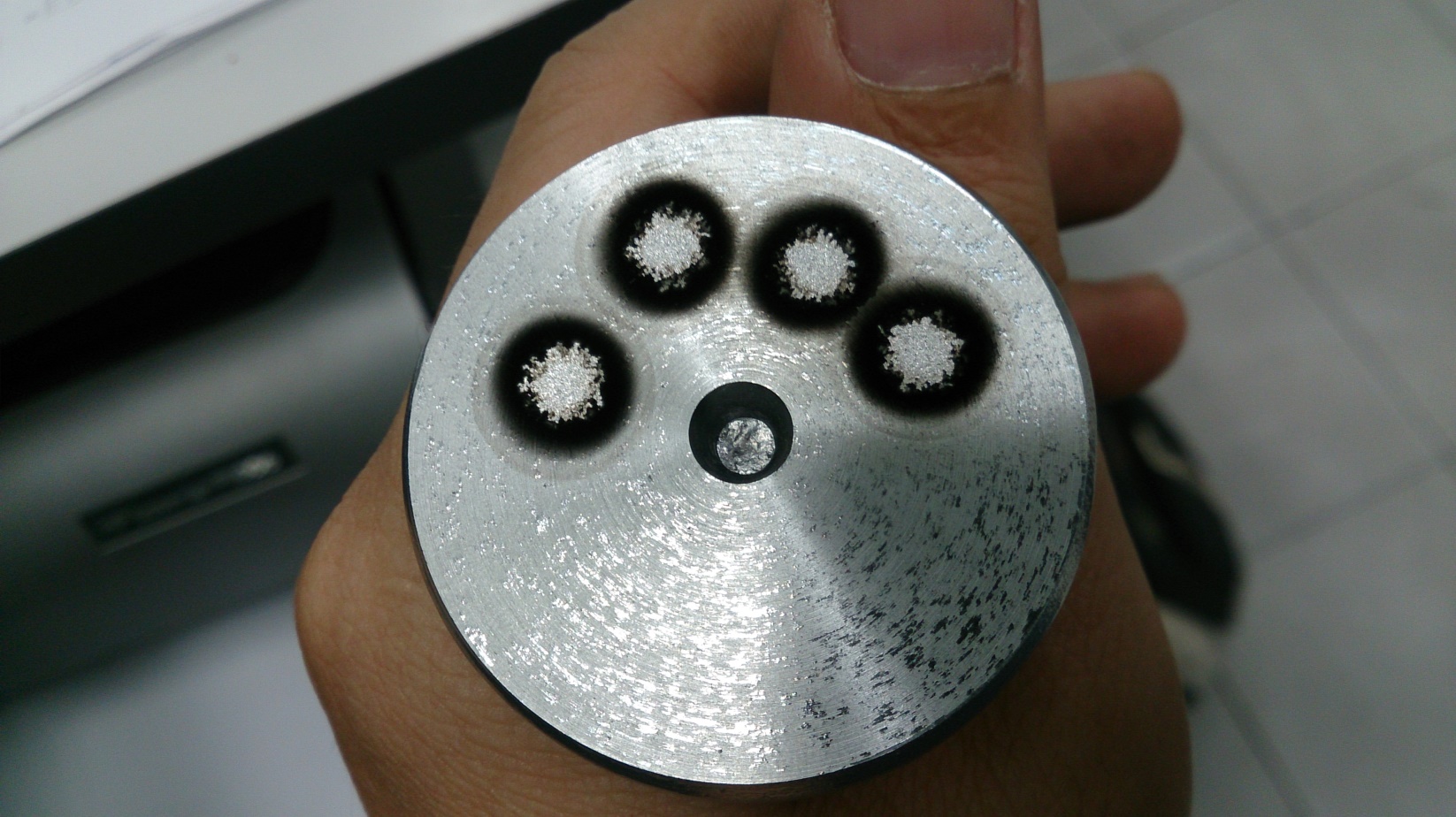

Spark marks on sample surface after analysis in Shimadzu PDA-7000

By using the spectrophotometers to determine the chemical composition of alloys, thereby identifying materials such as carbon steel, stainless steel, low alloy steel, cast iron, etc.

There are many factors that affect the determination of the chemical composition of materials such as the metallurgical process, the operation of the analyzer user, etc. The preparation of the surface of the sample is also an important factor in determining the optimum result when applied to the analyzer on the spectrophotometer.

Requirements for sample preparation:

- Samples are taken, shaped using specialized tools and can be cooled during sampling, but not wet during analysis.

- After preparing the surface, if the sample is hot, cool it by placing on a copper substrate and not contacting the surface of the analysis.

- Do not cool the sample after preparing the surface with liquid.

- Do not touch the surface of the analysis with pollution sources: finger, clamp, etc.

- The whole surface must be clean, the surface of the sample and the contact surface of the sample holder must be parallel.

- After preparation of the surface should immediately analyze.

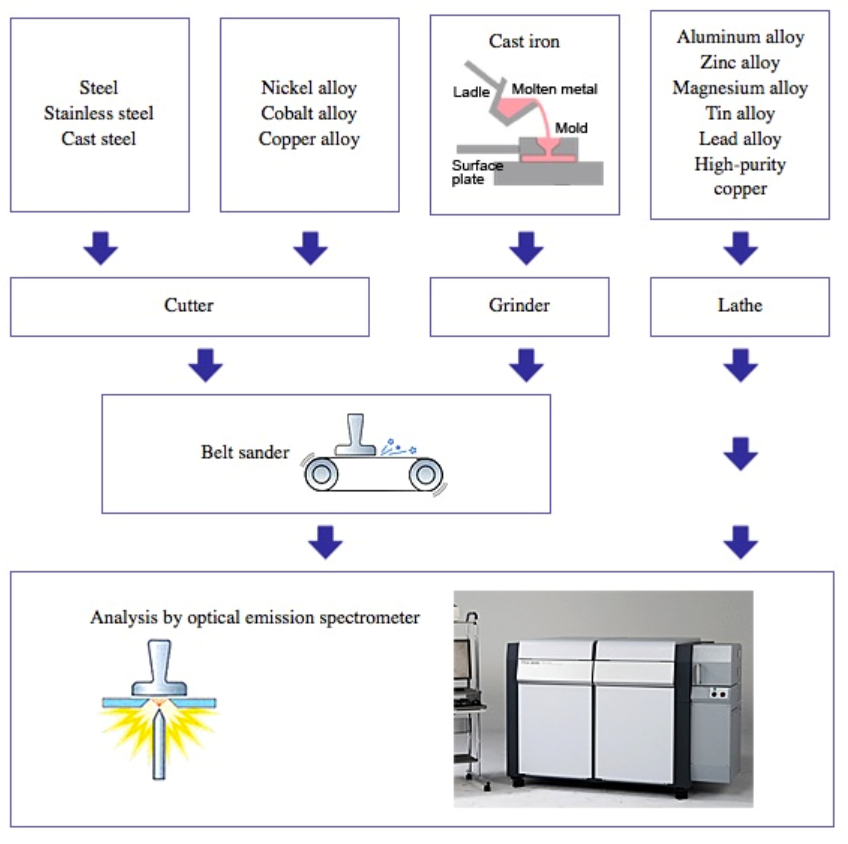

For different materials, sample preparation is a bit different:

- For samples of steel, cast iron ...: using the machine to cut or the mold for shaping and cooling the material after that surface is processed by grinding machine.

- For samples from the zinc - copper - aluminum group: lathes should be used to treat the sample surface before analysis.

The following is an illustration of the process of preparing a sample of common materials:

Diagram of preparation of analytical samples for some common materials

Source: ETA

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM