News

Shimadzu Releases the Xslicer SMX-6000 Microfocus X-Ray Inspection System

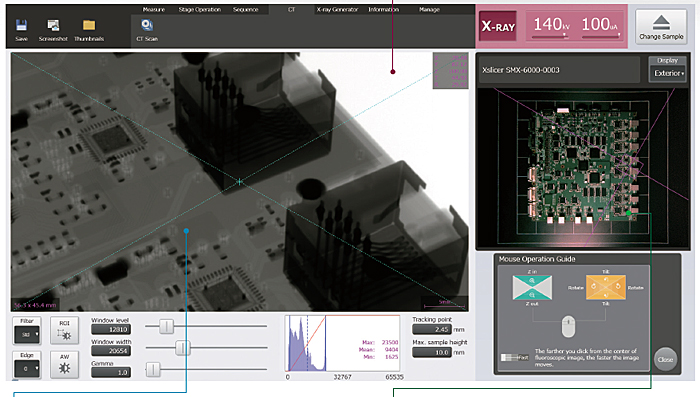

January 7, 2016. Shimadzu Corporation announces the release of the Xslicer SMX-6000 microfocus X-ray inspection system for non-destructive inspections. This is the first Shimadzu system to include inclined fluoroscopy and CT imaging functionalities in a single package and which is capable of obtaining cross-sectional images immediately after inclined fluoroscopy.

Figure 1. Xslicer SMX-6000

- Equipped with a Shimadzu microfocus X-ray generator and high-sensitivity flat panel detector and featuring CT scanning capability.

- Smooth and quick switching is now enabled between viewing fluoroscopic and cross-sectional images.

- The system includes a new Xslicer CT image processing engine used to fully automate calibration and provide high-speed scanning.

- The system can be used to observe distortion-free, high-magnification, and high-resolution images of detailed internal structures.

- Easy Operation.

- Easy CT Imaging.

- Easy-to-See Inspection Results.

- Automatic Image Quality Adjustment Function.

Figure 2. Interface of software

Industries:

The system can used in a wide range of applications such as:

- Inspection of Electronic Components: Digital camera, Lens, Connector, Power IC, Cell-phone, Chip inductor, Micro SD card…

- Inspection of Automobile Parts: Aluminum die-casting products, Micro turbine, Pressure sensor, Oxygen sensor, …

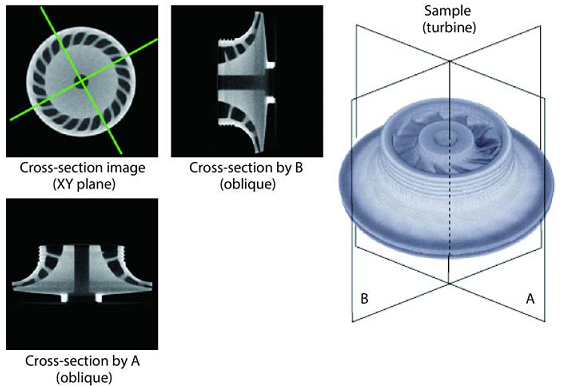

- Inspection of Turbine with oblique imagine.

- Motorbike parts,

- Health

- Other fields

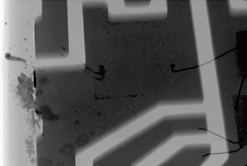

Damaged IC

Fluoroscopic Image Cross-Sectional Image Volume rendering Image

Figure 3. Fluoroscopic, Cross-Sectional, Volume rendering Images of Damaged IC

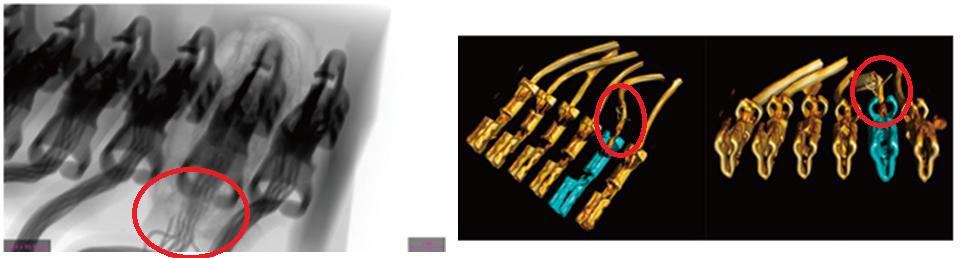

Heat-Damaged Connector

Fluoroscopic Image Volume rendering Image

Figure 4. Fluoroscopic and Volume rendering Images of Heat-Damaged Connector (The position in red circle is NG)

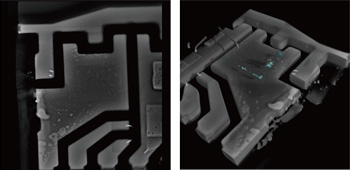

Figure 5. Oblique Images of Turbine

Source: ETA

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM