News

TESTING LCD DISPLAY PANEL WITH THE TEGAM MODEL 1750

A liquid crystal display (LCD) is a thin, flat panel used for electronically displaying information such as text, images, and videos. Their main uses include computer monitors, televisions, and instrument panels. Other applications range from aircraft cockpit displays to everyday devices such as video players, gaming devices, clocks, calculators and telephones. Today, with companies competing to stay alive in the harsh consumer market, LCD testing has become very important to ensure the product quality.

A typical LCD assembly consists of multiple layers of polycrystalline silicon interconnected with Indium Tin Oxide (ITO) conductors. ITO is used because it is a good conductor and optically transparent. The consistency and integrity of the ITO layer is important to the performance of the display and can be verified by measuring the conductance of individual ITO traces. A process goal is to minimize the use of ITO because it is expensive, but it must be deposited in sufficient thickness to be a good conductor.

|

Actual Resistance Test System |

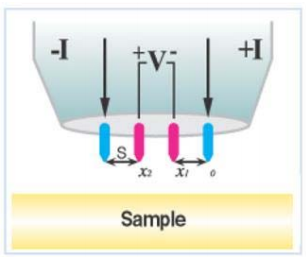

Resistance Testing on an LCD Panel |

To properly verify the conductance of ITO traces requires an instrument that can measure milli-ohm values accurately at very high speed. TEGAM offers the Model 1750 High-Speed, Precise, Programmable Micro-Ohmmeter which is more accurate than most ohmmeters and DMMs without compromising measurement speed

Accurate milli-Ohm measurements require the detection of voltages in the milli- to nano-volt range. Because lead resistances create significant errors at these levels, a four-wire Kelvin lead configuration is required. The 1750’s four-wire Kelvin configuration minimizes lead resistance errors by using a regulated current source for the test signal. The 1750 is capable of measuring 1 mΩ with an accuracy of better than 1 µΩ in less than 36 msec. This allows for rapid trace thickness measurement on multiple locations of the LCD panel.

The 1750 is also designed to interface with either a PLC through discrete I/O points or a PC with GPIB and RS-232 communications. This makes it compatible with vast majority of automated systems. This same combination of features is also beneficial to manufacturers of solar panels, conductive coatings, bulk material resistivity and electroplating where measuring the thickness of a conductive material applied to a surface is important to the performance of the end product.

Source: TMC

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM