News

The influence of the elements on the properties of steel

Steel is an alloy containing iron, carbon and some other elements. There are over 3,000 different types of steel in the world. Every year, because of human development, researchers have invented new types of steel with remarkable features and characteristics that can solve many problems which cannot do in the past.

Each type of steel has different grades of steel. Steel grades differ in their physical and chemical characteristics due to the compositional adjustments and the proportion of materials added during the production process. Manufacturers control the rate of participation of these elements to produce the desired steel.

The characteristics and properties are determined by the chemical elements such as carbon, nitrogen, nickel, manganese, iron, sulfur ...

Carbon (C): Carbon is present in the steel to increase the corrosion resistance, hardness and durability for steel.

Chromium (Cr) is an important component in helping steel resist oxidation from the environment. Normally the chromium component is adjusted to an appropriate ratio in the alloy. The chromium ratio is present in the steel from 10.5% to 26%. When the chromium content is high, the rust resistance is also high. Chromium is added to create a transparent protective film on the surface of the steel that the naked eye cannot see. This film does not lose the shine of steel.

Nickel (Ni): Nickel is present in steel to help steel durability and toughness.

Manganese (Mn): Manganese is added to the steel to deoxidize during the melting process to prevent the formation of iron sulfide dirt causing the steel to crack.

Silicon (Si) and Copper (Cu): added in small amounts to resist metallic corrosion of sulfuric acid (H2SO4).

Nitrogen (Ni): When in the steel the content of carbon is low, the strength of the steel is not good, nitrogen is added in this case to increase it.

Molybdenum (Mo): is an additive added to prevent surface corrosion and cracks.

Sulfur (S): sulfur added to help increase machining efficiency.

Because the influence is very important to characteristics and properties of iron and steel, controlling the content of these elements is extremely important.

With more than 140 years of Shimadzu's accumulated experience in spectroscopy equipment, Shimadzu has introduced a range of medium-to-high-level emission spectrum analyzers to meet the requirements of analyzing and controlling elements in iron and steel which believed to be used in iron processing and manufacturing plants, steel such as: Kyoei, Honda, TISCO, ...

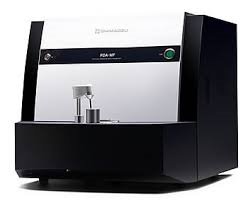

PDA – MF series: Compact with a high-performance CCD detector

PDA 5000/7000/8000 series: Excellent accuracy with PMT detector

Source: ETA

Others

- TECOTEC GROUP ATTENDED SHIMADZU’S SERVICE MANAGER MEETING IN 2022

- TECOTEC HANDED OVER EDX-7000 X-RAY FLOURESCENCE SPECTROMETER AT NIDEC CHAUN CHOUNG VIETNAM

- INSTALLATION OF CHIP PROCESSING SYSTEM – LANNER/ GERMANY

- TECOTEC completed installation of EDX-LE Energy dispersive X-ray Fluorescence spectrometer at DYT Vina

- TECOTEC DELIVERED AND INSTALLED THE 2ND X-RAY FLUORESCENCE SPECTROMETER - EDX-LE PLUS AT TABUCHI

- TECOTEC Group has handed over PDA-7000 Optical Emissions Spectrometers for Nihon Plast Vietnam

- Bowman XRF Coating Measurement System For Electroless Nickel Plating

- TECOTEC DELIVERED AND INSTALLED SMX-2000 SYSTEM TO NIDEC TECHNO MOTOR VIETNAM